The success of a manufacturing unit relies on consistent performance without taking a break where staff work in shifts, but machines don’t take a breather unless it’s maintenance downtime. This marvel can be set back by pushing a spanner into the cog wheel. But sometimes, problems like power cuts or bad weather can mess things up, halting work and causing delays. That’s where tough, reliable cables come in, they keep the electricity and internet running smoothly so production never skips a beat. A stitch in time saves nine, fixing small issues early avoids bigger headaches later.

One can learn more about JJ-Lapp’s innovations, which master innovative trends in cables that are made to handle extreme conditions while being kinder to the planet. The company stays ahead by producing high-tension cables that endure extreme heat and pressure. Some use materials that break down naturally over time, reducing waste. Others can withstand scorching heat without melting, perfect for factories where machines get hot. There are also “smart” cables with tiny sensors that check for wear and tear, sending alerts before a problem occurs. This means fewer surprises and less downtime.

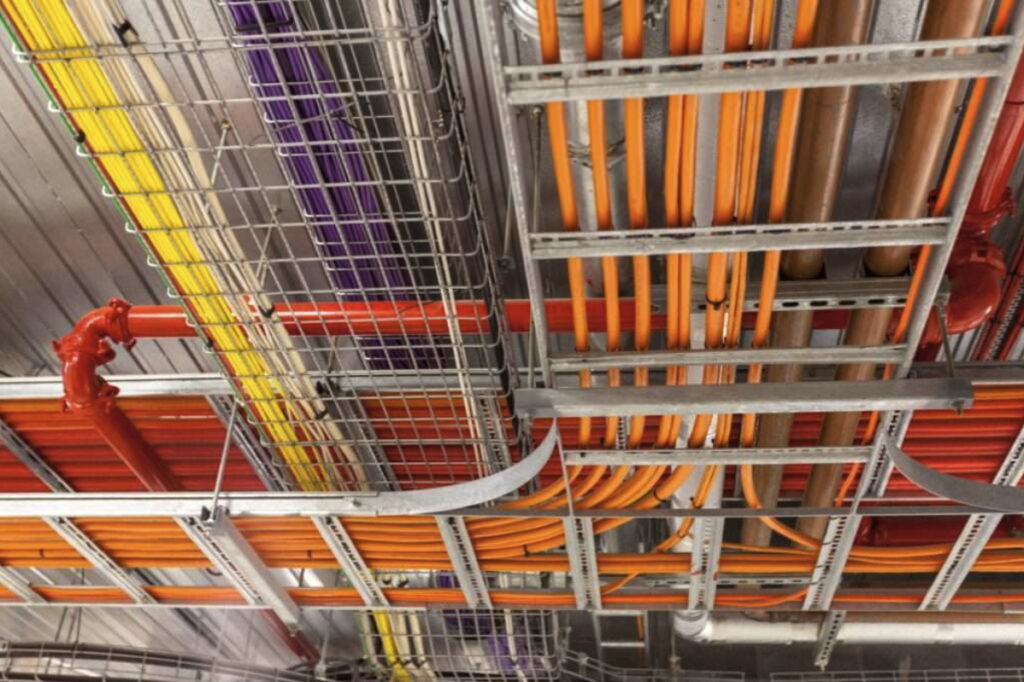

These upgrades make cables stronger, safer, and smarter. They don’t just carry power or data; they watch over the system, helping factories run smoother for longer. With better insulation and eco-friendly designs, they cut costs and waste while keeping everything connected. No more worrying about storms or overheating. It’s like having a backup plan built right into the wires, ensuring machines hum along without a hitch. The future of manufacturing relies on these small but mighty improvements, turning potential disasters into mere blips on the radar. Here is a brief description:

1. Tough-as-Nails Heat-Resistant Cables

These cables are built to handle the heat, literally. In factories where machines run non-stop, things can get scorching hot. Regular cables might melt or wear out quickly, causing dangerous shorts or fires. But these new cables have special insulation that lasts at high temperatures, staying cool under pressure. They’re like the fireproof suit for wires, keeping power flowing safely even in the hottest corners of the plant. No more shutdowns because the cables couldn’t take the heat.

2. Smart Cables With Built-In “Eyes”

These aren’t your average cables, they’re clever. Packed with tiny sensors, they constantly check their health, like a doctor monitoring a patient. If a cable gets damaged or starts wearing thin, it sends an alert before things go wrong. This means workers can fix small issues before they turn into big, costly breakdowns. It’s like a car warning you about low oil, but these cables alert you to fraying wires or weak connections. This leads to less guessing, fewer surprises, and machines that operate smoothly without any issues.

Conclusion:

The future of manufacturing isn’t just about bigger machines, it’s about smarter, stronger connections. These cables are the unsung heroes, fighting heat, preventing disasters, and whispering warnings before trouble strikes. They don’t just power factories, they protect them. Upgrade your lines, and watch productivity soar. The difference? It’s all in the wires. Don’t get left behind.